The Ultimate Guide to Slitter Rewinder Machines in the Paper Processing Industry

2024-05-30

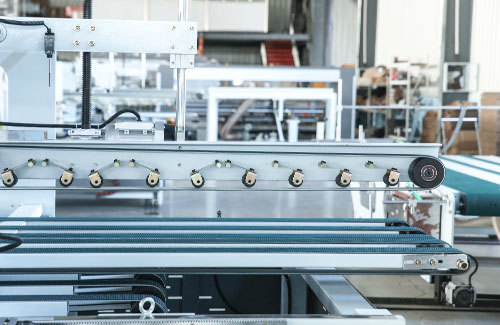

【SUMMARY】Slitter rewinder machines play a crucial role in the paper processing industry, specifically in the field of rewinding and cutting large rolls of paper into smaller, more manageable ones. These machines are essential for ensuring efficiency and precision in the manufacturing process.

Slitter rewinder machines consist of various components, including unwinding units, cutting blades, tension control

Slitter rewinder machines play a crucial role in the paper processing industry, specifically in the field of rewinding and cutting large rolls of paper into smaller, more manageable ones. These machines are essential for ensuring efficiency and precision in the manufacturing process.

Slitter rewinder machines consist of various components, including unwinding units, cutting blades, tension control systems, and rewinding units. The unwinding unit feeds the large paper rolls into the machine, while the cutting blades accurately slice the paper into smaller widths. The tension control system ensures that the paper is properly stretched and rewound onto the smaller cores in a uniform manner.

There are different types of slitter rewinder machines available, such as duplex slitters, turret slitters, and center slitters, each offering unique features and capabilities to meet specific production needs. It is essential to choose the right type of machine based on the volume and type of paper being processed.

Maintenance is key to ensuring the optimal performance of slitter rewinder machines. Regularly cleaning and lubricating the machine, inspecting and replacing worn-out parts, and ensuring proper alignment of components are essential maintenance practices that can prolong the lifespan of the equipment and prevent costly breakdowns.

In conclusion, slitter rewinder machines are indispensable tools in the paper processing industry, providing efficiency, accuracy, and reliability in the rewinding and cutting of paper rolls. By understanding the key components and maintenance practices of these machines, manufacturers can optimize their production processes and ensure high-quality output.

Slitter rewinder machines consist of various components, including unwinding units, cutting blades, tension control systems, and rewinding units. The unwinding unit feeds the large paper rolls into the machine, while the cutting blades accurately slice the paper into smaller widths. The tension control system ensures that the paper is properly stretched and rewound onto the smaller cores in a uniform manner.

There are different types of slitter rewinder machines available, such as duplex slitters, turret slitters, and center slitters, each offering unique features and capabilities to meet specific production needs. It is essential to choose the right type of machine based on the volume and type of paper being processed.

Maintenance is key to ensuring the optimal performance of slitter rewinder machines. Regularly cleaning and lubricating the machine, inspecting and replacing worn-out parts, and ensuring proper alignment of components are essential maintenance practices that can prolong the lifespan of the equipment and prevent costly breakdowns.

In conclusion, slitter rewinder machines are indispensable tools in the paper processing industry, providing efficiency, accuracy, and reliability in the rewinding and cutting of paper rolls. By understanding the key components and maintenance practices of these machines, manufacturers can optimize their production processes and ensure high-quality output.

TAG:

Recommended News

Service hotline

Cangzhou Mingyang Machinery Co., Ltd

Tel:+86 13803173756

Email:christina@mingyang-machinery.com

Add1:Packaging Industrial Zone, Dongguang County, Cangzhou City, China

Add2:1108-1109, Tower A, Taurus, Wuyue Square, Yunhe District, Cangzhou City