Product

Contact

Whatsapp: +8613803173756

Mobile:+8615803175616

Email:christina@mingyang-machinery.com

Add1:Packaging Industrial Zone, Dongguang County, Cangzhou City, Hebei Province

Add2:1108-1109, Tower A, Taurus, Wuyue Square, Yunhe District, Cangzhou City

MHC-001

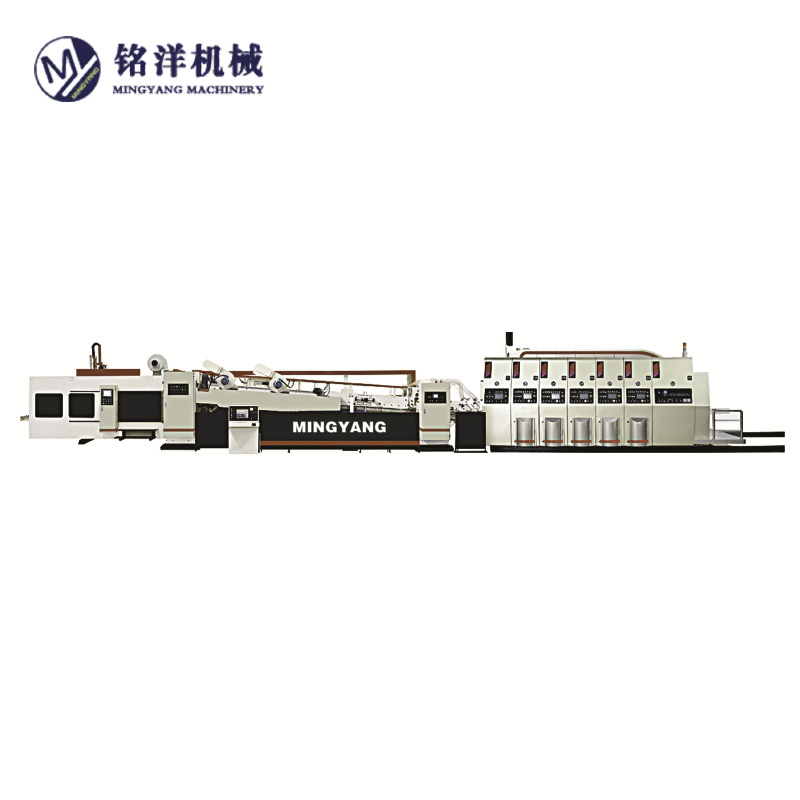

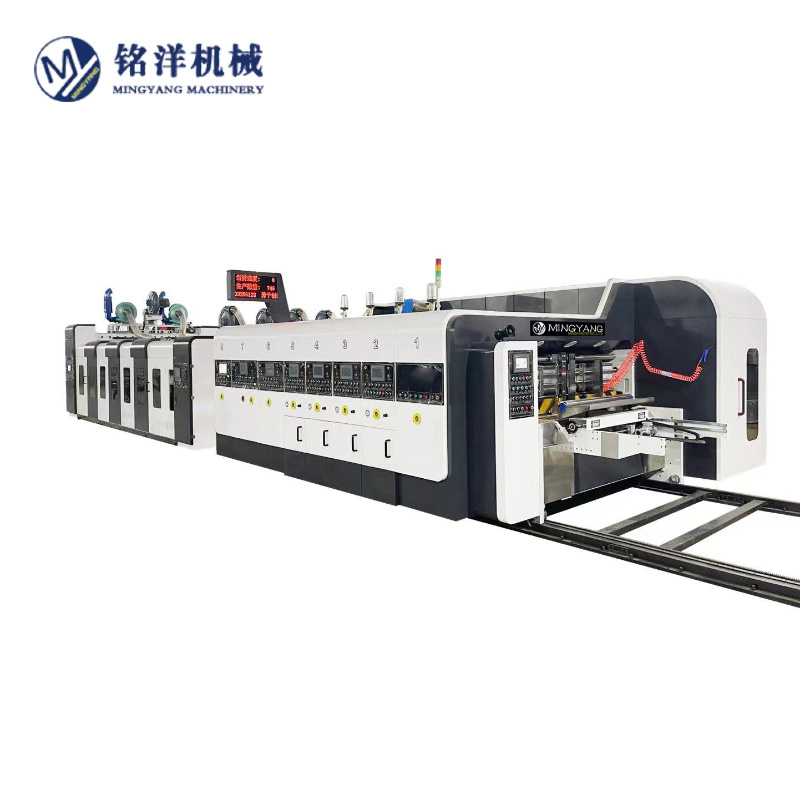

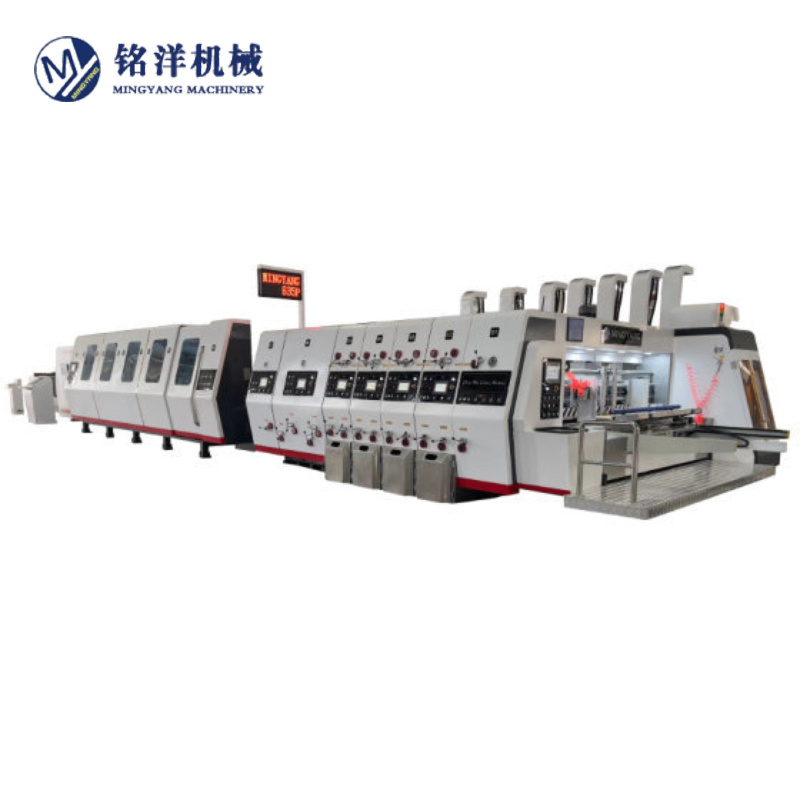

Full-automatic Leading Edge Paper Feeding Flat Pressing Die Cutting Machine (f Series)

The high-speed precision front paper feeding device can stably transport various types and qualities of corrugated paper, with strong adaptability and wide working range.

key word:

Category:

- Product Description

- Technical Parameter

-

- Commodity name: Full-automatic Leading Edge Paper Feeding Flat Pressing Die Cutting Machine (f Series)

- Commodity ID: MHC-001

F/FC series leading edge paper feeding section

The high-speed precision front paper feeding device can stably transport various types and qualities of corrugated paper, with strong adaptability and wide working range. A special polyether paper feeding rubber wheel is used in conjunction with a fence holder and air cushion to ensure accurate delivery and positioning of the warped cardboard. Frequency conversion air suction fine adjustment device to adapt to the paper feeding requirements of different thickness corrugated from F to 5 layers.

EF/EFC series lower suction tray feeding section

The lower suction tray type non-stop paper feeding method is adopted, and the pneumatic side push baffle plate is used to push and tidy the paper stack in advance. The vacuum adsorption method is used to feed the cardboard into the paper pressing roller, which is not easy to scratch the printing surface.

Paper feeding table side positioning part

-

Category/Model MHC-1100F/1100FC MHC-1300F/1300FC MHC-1500F/1500FC MHC-1650F/1650FC MHC-1900F/1900FC MHC-1100EF/1100EFC MHC-1300EF/1300EFC MHC-1500EF/1500EFC MHC-1650EF/1650EFC MHC-1900EF/1900EFC Paper format 1100×790mm 1290×940mm 1500×1100mm 1650×1200mm 1900×1400mm Paper format 470×420mm(F/FC) 470×420mm(F/FC) 470×420mm(F/FC) 550×500mm(F/FC) 650×550mm(F/FC) 470×450mm(EF/EFC) 470×450mm(EF/EFC) 470×450mm(EF/EFC) 550×500mm(EF/EFC) 650×550mm(EF/EFC) Die-cutting format 1070×770(mm) 1280×920mm 1480×1080mm 1620×1180mm 1870×1380mm Working speed 7000s/h 5000s/h 5000s/h 4000s/h 3500s/h Edge width 12mm 12mm 12mm 12mm 12mm Bite width 6-12mm 6-12mm 6-12mm 6-12mm 6-12mm Knife-edge height 23.8mm 23.8mm 23.8mm 23.8mm 23.8mm Electric knife requirements 380V,50HZ,3PH 380V,50HZ,3PH 380V,50HZ,3PH 380V,50HZ,3PH 380V,50HZ,3PH Compressed air pump Air compressor displacement 1.05m ³/ min,12kg/cm ²-- User provided Main motor power 11kw 11kw 15kw 15kw 18.5kw Working pressure 300T 300T 300T 300T 300T Total weight of the machine 16T(F/EF)/17T(FC/EFC) 18T(F/EF)/19T(FC/EFC) 20T(F/EF)/21T(FC/EFC) 22T(F/EF)/23T(FC/EFC) 28T(F/EF)/29T(FC/EFC) Overall size 7000×4250×2370mm(F/EF) 7400×4510×2300mm(F/EF) 8100×4710×2300mm(F/EF) 8230×5140×2500mm(F/EF) 8700×5880×2530mm(F/EF) 8000×4250×2370(FC/EFC) 8760×4510×2300(FC/EFC) 9140×4710×2300(FC/EFC) 9580×5140×2500(FC/EFC) 10260×5880×2530(FC/EFC) Applicable Paper Range E, B, C, A, and AB corrugated paper

Welcome To Leave A Message

Service hotline

Cangzhou Mingyang Machinery Co., Ltd

Tel:+86 13803173756

Email:christina@mingyang-machinery.com

Add1:Packaging Industrial Zone, Dongguang County, Cangzhou City, China

Add2:1108-1109, Tower A, Taurus, Wuyue Square, Yunhe District, Cangzhou City